Radon measurements

Radon measurements

IAF has officially been appointed to measure radon in workplaces and dwellings

Radon in buildings and workplaces has recently moved into the limelight of public and regulatory attention. In radon-affected areas, new legal requirements have had to be followed since 2018 in newbuilds and workplaces.

For many years IAF has been a highly acclaimed service provider of radon-related services. IAF is accredited for the measurement of indoor radon concentration under ISO 17025. Our staff include officially Certified Radon Experts. IAF jas officially been approved by the Federal Office for Radiation Protection for radon measurements at workplaces according to Art. 155 of the German Radiation Protection Ordinance (2018).

Our services include, but are not limited to, the following:

- Short- and long-term measurements of radon and radon progeny, and/or the potential alpha energy concentration (PAEC), determination of the equilibrium factor.

- We only use passive radon detectors from officially recognized manufacturers (e.g., ALTRAC) for long-term measurements. The delivery to, or installation at, the client's premises takes a few days.

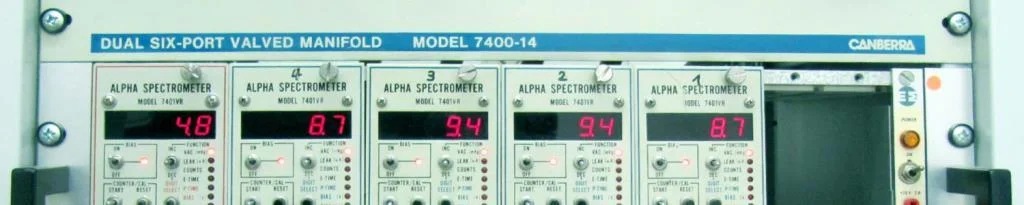

- Use of active radon monitors for time-resolved radon measurements (Radon Scout, AlphaGuard, etc.): With more than 80 radon monitors, IAF has at its disposal one of the largest equipment parks of radon monitors in Europe. This enables us to implement even the most complex indoor radon characterisation tasks in buildings with a large number of rooms.

- Time-resolved and correlated measurements in multiple rooms to determine the dynamics and convective flow patterns of radon and radon intrusion pathways.

- Determination of the "radon potential" of soil prior to the erection of newbuilds, and radon measurements during / after construction. Depending on the specific requirements, we use different measuring systems ("Czech soil probe", "Bonn soil probe"). Apart from the determination of the activity concentration of radon in soil air, IAF also IAF measures the air permeability of the soil. Measurement usually includes 3 points a few meters apart.

- Test of the radon tightness (via the radon diffusion coefficient) of building materials such as sealing liners, floor coatings, collars etc. using a double-chamber method according to to DIN ISO 11665-13.

- Determination of the radon exhalation rate of materials (Bq/m2 s), especially exhalation of radon from building materials.

- Blower Door Tests equivalent to DIN ISO EN 13829.

- Consulting and independent advice on radon and related mitigation measures for public and private buildings.

- Planning and implementation of radon monitoring programs, modelling of radon exhalation and transport, and conceptual development of radon mitigation measures.

Before we start measuring radon in buildings, at workplaces or in the ground, we discuss the precise objective(s) with the client. This is the only way we can avoid "flying blind" and specifically answer our client's questions and find solutions that work. Depending on the problem, we measure the radon concentration with radon monitors (short-term measurements) or carry out long-term measurements with solid-state nuclear track detectors (usually over 12 months).

The implementation of legal requirements and recommendations with regard to the radon situation in buildings and at workplaces requires a high level of competence, experience, as well as appropriate measurement equipment, and knowledge to interpretate the results, in order to avoid failure of mitigation measures. For decades, IAF has been at the forefront of radon measurements and mitigation measures.

In addition to “conventional” radon (Rn-222), we also offer measurement of the short-lived thoron (Rn-220) relevant in the context of the natural Th-232 decay series.

Our guidelines for radon measurements

IAF have developed extensive internal guidelines, procedures and work instructions for carrying out radon measurements in order to achieve results of the highest quality. This includes, but is not restricted to, the following points that are often overlooked:

- Selection of the optimal, problem-specific measurement equipment.

- Ensuring regular maintenance and calibration of all devices.

- Correct positioning of the Rn monitors in the room or building.

- Complementary measurement of other radiological and non-radiological parameters (e.g., atmospheric pressure, temperature) for proper interpretation of the measurement results.

- Detailed records and documentation of the measurement environment and results.

- Special notes and memos on typical, but perfectly avoidable, errors, which repeatedly lead to misinterpretations and costly failures.

Radon measurements

Radon measurements